Speaker pursuit road > the technological chapter of woodwork top of Oyama [mikioto] >

The edge is good way 1 to occupy the shroud ..sleep.. to use BH.

The most general method might be a method of the joint as the shroud is worn in the sandwich at the end after all the sound road parts are assembled though backing loading horn speaker is possible various ways of making. The edge has a little knack when getting damp and can connect sleep even by oneself in this method perfectly by understanding it.

The little knack is to use "Temporary stop nail". Because the temporary stop nail does the role that the board that attaches the bond hangs of hanging to prevent it from slipping, place decision of the board can be done in the exact location, and the edge (Or, stop it the machine screw) comes to be put. The principle is quite the same though the machine screw in the impact is chiefly used for the machine named pin Tucker on the site of woodwork.

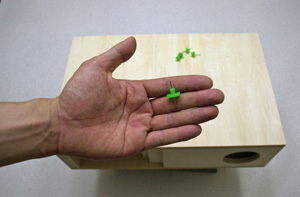

| This is "Temporary stop nail. " |

| Temporary stop [kugi] is stricken from the table to four corners of the board. It is stricken to length that it penetrates by about 2-3milli [kugi] ahead. |

| The point of the nail goes out a little when upsetting it. |

| Enough bond is painted on the sound road part of backing loading horn. |

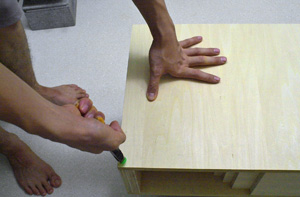

| It puts and it searches for a correct position with shroud [woso] [-] with the temporary stop nail of which the point goes out a little. |

| When the place is decided, pressure is put on, and the temporary stop nail is driven with the hammer to the last minute. |

| It presses it with [tagane] hanging of the board in this ..hanging.. because it doesn't slip to one's heart's content. |

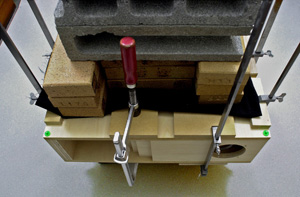

| The weight is put on the sound road part and it turns the heat. (The machine screw of here is acceptable. ) |

| When bonding ends, the temporary stop nail is pulled out with pincers. |

| The hole of the temporary stop nail disappears when it irons wet Wess and it kicks. |