Speaker pursuit road > the technological chapter of woodwork top of Oyama [mikioto] >

Notes of Swan speaker production

The Nagaoka [tetsuotoko] teacher was left the design of a lot of Swan speakers with super-Swan, Swan a, the flamingo, [su-pa-furaminko], the rhea, and the moa. A basic structure is almost the same. Making goes up compared with backing loading horn of a usual CW system, and it is complex and the difficulty of production goes up, too. Upper above everything else point to produce is to make the body part in the accurate hexahedron not distorted though Oyama also grew the seed how many in the past. The sound road part is not bonded to the shroud, the bottom plate, and the top board well if this cannot be done and it causes the horn sound leakage.

| Bonding the board of the first step is completed. |

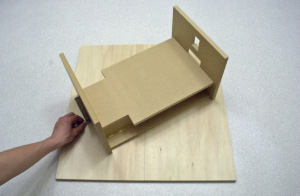

| Positioning the board bonded afterwards is the most important. |

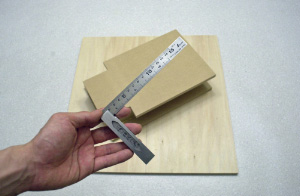

| Tool to confirm right angle that is called [sukoya] |

| The board of which the plane has gone out is paved below. The top board and the bottom board in Swan are temporarily put and the right angle is confirmed from both sides. |

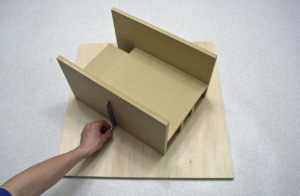

| A right and left shroud is checked without fail. The right angle is confirmed from four directions, the position of the second step is fine-tuned, and it decides it. |

It is necessary to position the third step similarly though the importance of positioning the board in the second step part where it finished making the first step was written in the explanation of the photograph.