Speaker pursuit road > the example of producing Nagaoka [tetsuotoko] speaker top >

Production 4 of D-88 super-flamingo

| 31 |  |

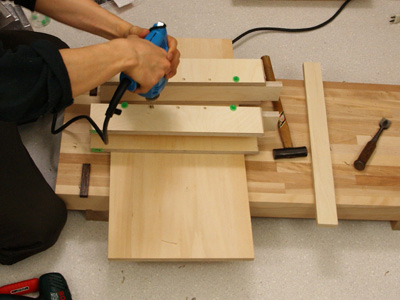

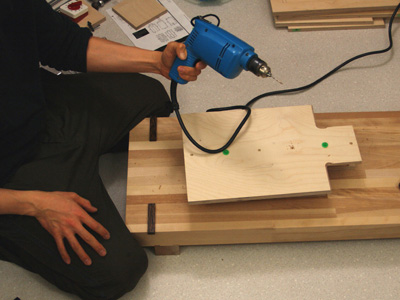

| The machine screw is put before the bond finishes drying (In about 30 minutes). Used it this time blue, electric drill and green rechargeable drill driver. First of all, the hole in the under is made by an electric drill and, next, a drill driver spends the machine screw. It is very efficient to use two at the same time though as much as only one drill driver can do when thinking about time when a drill blade is changed for the driver bit. It was a slender thread because it had caused the board crack that it made the done hole about [finrandoba-chi] used for construction. | |

| 32 |  |

| When the hole in the under is made, the machine screw is put. All the machine screws were occupied by repeating this work this time. | |

| 33 |  |

| 7+8+9+ puts L and R and the adhesive is put at the same time. | |

| 34 |  |

| The lid of the bottom board and the top board doesn't close well at the end when the by far can be done here. The board is appropriated right and left and it is noted that there must not be by far. | |

| 35 |  |

| About one three weight 12k that upsets one and is is put. | |

| 36 |  |

| The driver puts the machine screw when doing for about 30 minutes. | |

| 37 |  |

| 10+11 also makes LR at the same time. | |

| 38 |  |

| (3+4+5)(10+11) is completed with (7+8+9). | |

| 39 |  |

| It bonds to 1+2+3+4+5+6 [kokoha] riot with the woodwork bond. | |

| 40 |  |

| A positional confirmation is done accurately before the bond dries. The board is appropriated from the under and the by far in the board of four confirms whether. |