Speaker pursuit road > the example of producing Nagaoka [tetsuotoko] speaker top >

Production 6 of D-88 super-flamingo

| 51 |  |

| When the place is decided, the weight is driven and the machine screw is driven to [jojo] when entering the state of putting half [kawa] coming. It crowds in hole under �� fixing drilling it in clamping so as not to shift ..the opened �� machine screw... This repetition. | |

| 52 |  |

| This is important though it is repeatedly written the time of half [kawa] coming a little while ago. It hardens the peel is not in the meaning because the space is not buried though [tsuyo] degree might increase somewhat either. If the bond overflows after driving the machine screw, it is evidence in the leather-hard state. | |

| 53 |  |

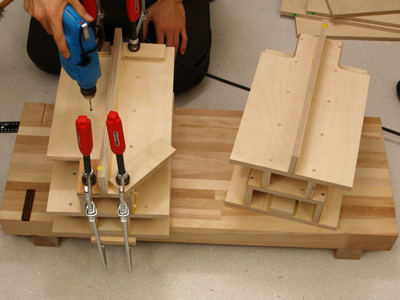

| 10+11 is bonded. Here also repeats the previous process and the same thing. The right angle is confirmed without fail. | |

| 54 |  |

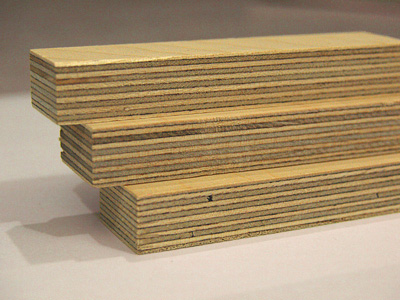

| If hardness that [finrandoba-chi] is terrific uses an electric drill, any person should understand at once. Be hard, hard, and ��� The blade has not advanced easily. | |

| 55 |  |

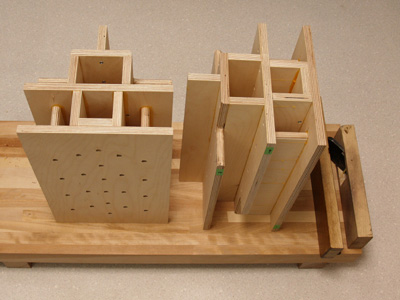

| (1+2+3+4+5+6) and bonding of (7+8+9) + (10+11) are completed. | |

| 56 |  |

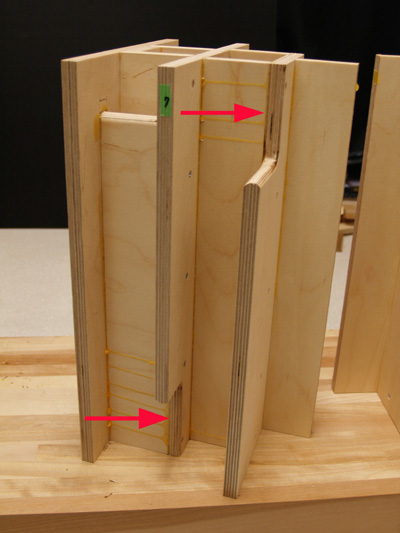

| It installs on only about 0.2mm this time though the by far of about 1-2mm can be done every time in the red arrow part. | |

| 57 |  |

| Because here is an important place that the sound passes, let's pay the by far with [kanayasuri] and the emery paper. Such a mere trifle leads to the tone quality improvement. | |

| 58 |  |

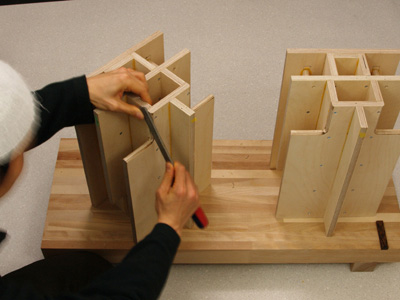

| It bonds in order of 13, 12, and 14. | |

| 59 |  |

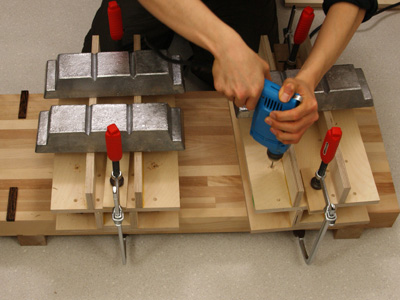

| The edge sleeps in the bonded part, and clamping is put. The batten is appropriated to the place where it touches the surface without fail and the surface is prevented being damaged. In addition, it drops perfectly by handling Wess that the bond gets wet. | |

| 60 |  |

| It is a machine screw stop to the part where the pressure of clamping doesn't hang. The drill, and it is [akeru] �� drill driver and machine screw stop of the hole in the under. |