Speaker pursuit road > the example of producing Nagaoka [tetsuotoko] speaker top >

Production 1 of D-37

| 1 |  |

| Production start. Parts of (1+2+3+5+6) are made. Board of one. | |

| 2 |  |

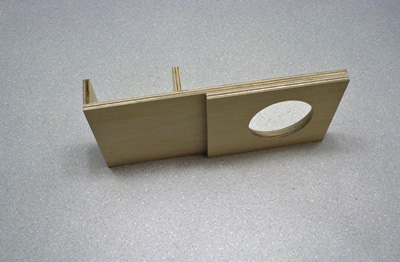

| The board of two is bonded. | |

| 3 |  |

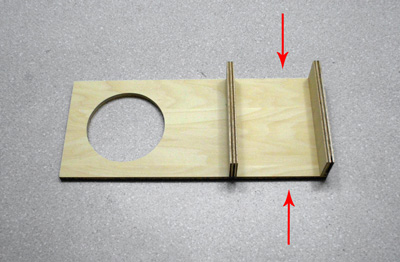

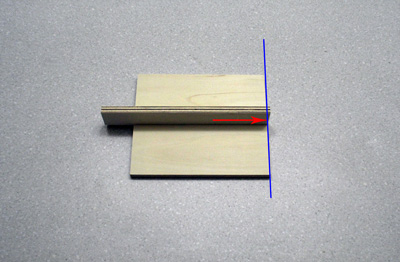

| The board of three is bonded. The most important thing in the assembly of the speaker of important [konsutantowaidosu] (width of the sound road constancy) is to prevent irregularity from going out right and left when the part that becomes parts of the sound road is assembled. Confirm whether the board is appropriated from the direction of the arrow and there is space. All parts to 1-28 are similarly checked. | |

| 4 |  |

| The board of five is bonded. | |

| 5 |  |

| The board of six is bonded. | |

| 6 |  |

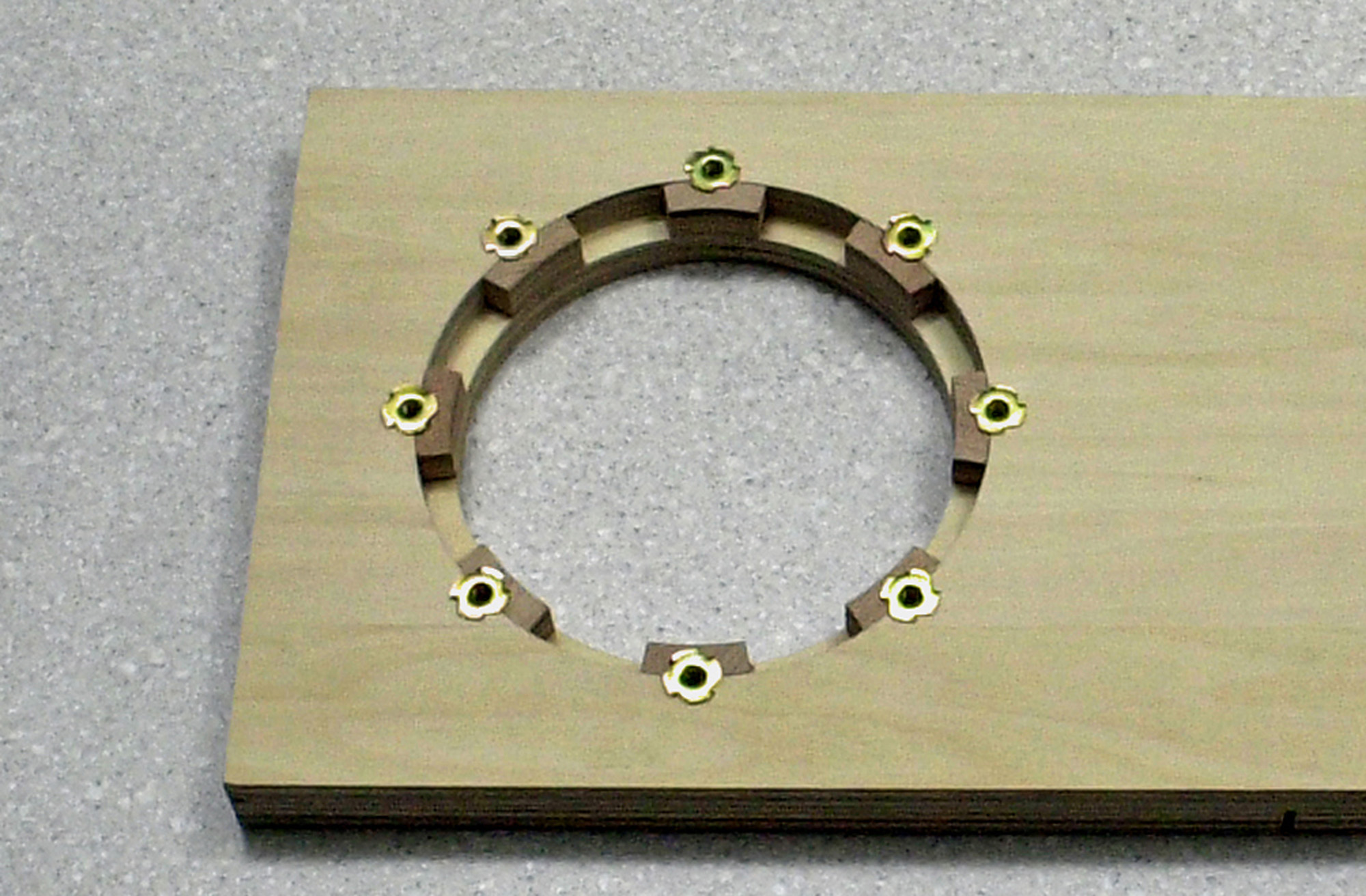

| The nut is installed at the time of this (Before installing parts in the board on the side) when the nut with the tab is used. The nut cannot be installed well as shown in the photograph if the scrap piece of wood is processed and it doesn't bite. This is because the use of the wood screw is required though diameter ��150 and inside diameter is 170�� an outside board the tree removing of D-37. The method of cutting down between nuts by the drill after the diameter of an inside, outside board is made same ��170 is one to use the nut with the tab. | |

| 7 |  |

| (7+8)It drinks and parts are made. Board of seven | |

| 8 |  |

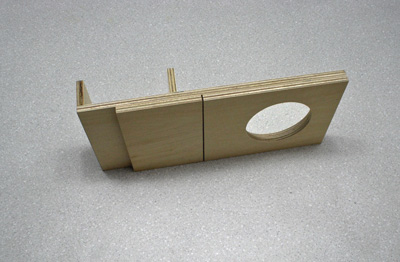

| The board of eight (board of reinforcement) is bonded. The last bonding goes well when some (About 0.5mm) boundaries of the board of 7 and 8 are beetling without exactly joining it in the direction of a red arrow. (Even if it doesn't adhere perfectly, 8 23 are the problems on tone quality. ) | |

| 9 |  |

| (9+10)It drinks and parts are made. Board of nine. | |

| 10 |  |