Speaker pursuit road > the example of producing Nagaoka [tetsuotoko] speaker top >

Production 3 of D-88 super-flamingo

| 21 |  |

| When it was a trimmer, it completed it in one minute though it took [goshigoshiyaru] and about one hour in [kanayasuri]. It was possible to process it beautifully. | |

| 22 |   |

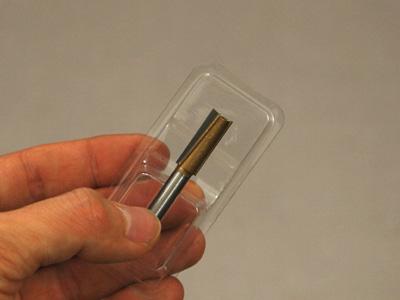

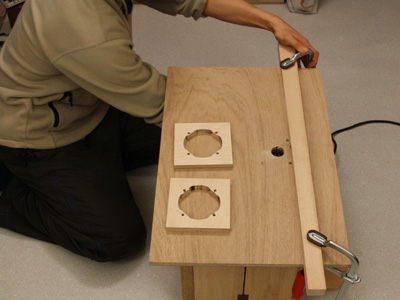

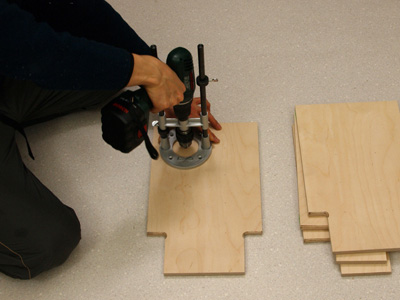

| ..spot-facing.. processing is continuously put. This is a processing given so that the terminal on the unit side may smoothly pass to the baffle. The trimmer table is used here. It processes it by using a straight bit. Because [handoru-ta-] is used and has been set by [ubeki], [konanodega], and the trimmer strictly making the treatment device, here has been brought together. | |

| 23 |   |

| Because the blade becomes baring as for this processing, it involves risk. | |

| 24 |  |

| The rounding part was made a square with the chisel. | |

| 25 |  |

| Because the place where it did not put on pressure easily had been understood, the machine screw stop decided to be done there though everything was bonded with the bond without using the machine screw last time. As a result, increasing the shelter density and strength in the horn aims. | |

| 26 |  |

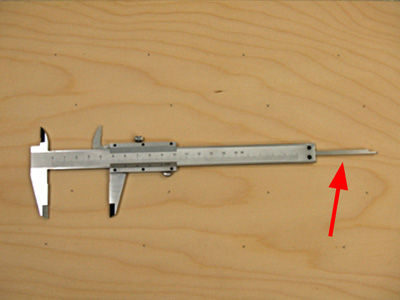

| But when the space can ..place where the machine screw stop is done.. be chiefly done in the sound road part, the place is center but avoiding. tone quality deterioratedIt is possible to settle in the riot in the place where the machine screw stop is done. When hips of calipers are used, it is early. | |

| 27 |  |

| The place where the machine screw stop is done is scheduled to conceal all wood screws in the place where it touches externals in Dubbo. All were [ireru] because it thought that the adverse effect went out to tone quality when the head of the machine screw jumped and it went out as for spot-facing though you may drive a wood screw as it is because it did not see an inside sound road part. | |

| 28 |  |

| When everything is opened at a time by the use of all bench drilling machines and vertical drills after it calculates, the place stopped with the machine screw is efficient. It takes serious time to put out the drill whenever bonding. When the number of made holes is counted, the machine screw will be driven by as much as 108 places per one speaker. | |

| 29 |  |

| The processing was completed spot-facing ..all the hole opening... Even here is a preparation stage in this though indeed excellently in was turned over. It enters for assembly here. | |

| 30 |  |

| (3+4+5)It bonds with clamping at the same time two [wo]. The right angle is confirmed with [sukoya]. It is a caution needed because it becomes not right-angled if the edge unskillfully puts sleep. |