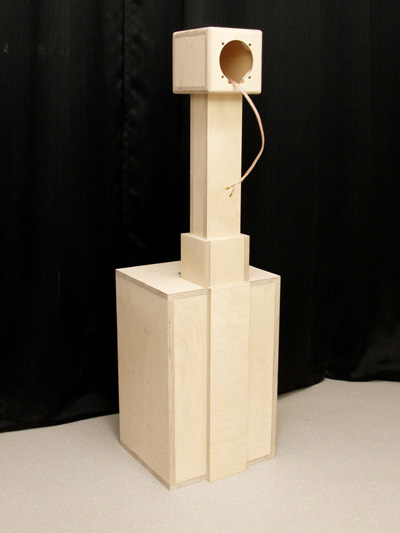

Speaker pursuit road > the example of producing Nagaoka [tetsuotoko] speaker top >

Production 10 of D-88 super-flamingo

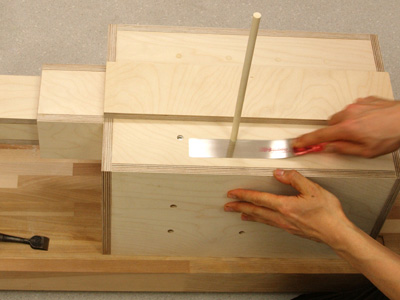

| 91 |  |

| The Dubbo burial in the hole in the part where the machine screw was stopped is done to the riot. | |

| 92 |  |

| Bali is taken with [kode] cutting �� chisel without �� littleneck clam that buries �� Dubbo spread on surroundings with �� toothpick that puts the bond in the hole. This work is single-mindedly repeated. | |

| 93 |  |

| Place in which Dubbo of the same size on the way is lost and it makes it with plane in haste. It seems to be difficult and considerably easy. | |

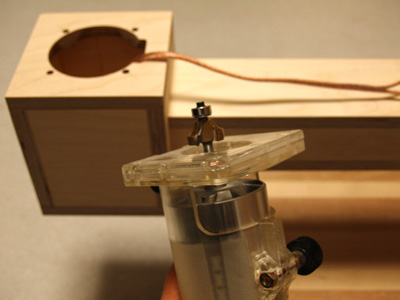

| 94 |  |

| The chamfering of the baffle is continuously processed. Here handles the trimmer. The largest R8.5 in the Boas side bit is used. It finished it up with the plane and paper. (Perhaps, it costs about 10,000 yen only by the bit though it is possible to do if [handoru-ta-] is used when the same 15R as board thickness is taken. ) Do not cut down at a time a lot, and divide the amount of cutting into several-time about the knack when it cuts down by the trimmer. Think about the direction where the trimmer is operated beforehand. Do not stop the trimmer on the way (Because [zai] scorches). | |

| 95 |   |

| Scorching was dropped by using the sandpaper of # 120 because it peeled off and [zai] had scorched a little according to the expectation when the trimmer applied R of the head. In that case, it keeps beautiful when there is a paper appropriating to which R attaches a little. It is possible to buy it if looking for in the do-it-yourself store. | |

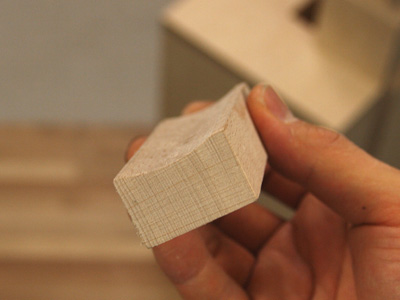

| 96 |  |

| Foundation by the sandpaper is continuously adjusted. The 240th yarn numbers are used. The batten is appropriated and the head problem part is done by the hand work. It is because the corner rounds when Sanda is handled to a detailed part. Electric Sanda was handled to the body part. | |

| 97 |  |

| Assembly is completed by this. | |

| 98 |  |

| It has hung for as many as three weeks by installing the unit completion. | |

| 99 |  |

| When seeing from the back. |